Tobe

Editor's Column "Craft Production Regions" VOL.4 AD

VOL.1-4

Update

VOL.1-19

Update

VOL.1-17

Update

VOL.1-43

Update

VOL.1-2

Update

VOL.1-3

Update

VOL.1

Update

VOL.1-7

Update

VOL.1-32

Update

VOL.1-26

Update

VOL.1-12

Update

VOL.1

Update

We share a variety of information and perspectives on Japanese crafts, including exhibition information and interviews.

Editor's Column "Craft Production Regions" VOL.4 AD

KOGEI Topics VOL.19

New Products VOL.17

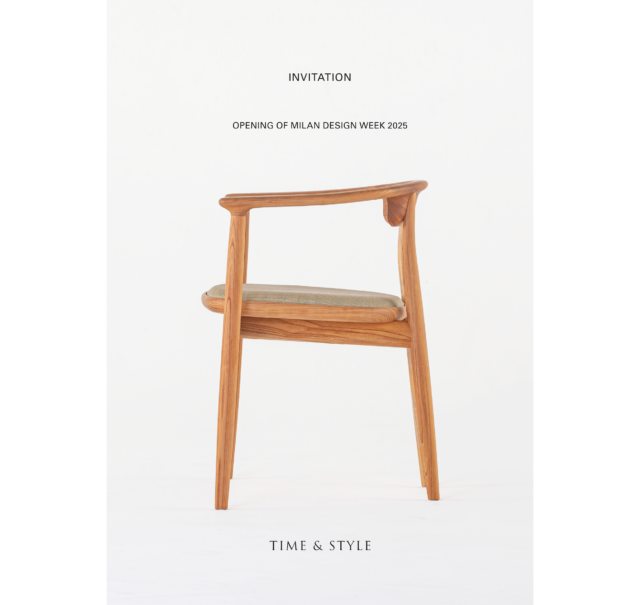

Featured Exhibitions & Events VOL.43

Apr 5 – Jun 22, 2025

SEIKADO BUNKO ART MUSEUM

Apr 8 – May 6, 2025

The Gotoh Museum

Apr 11 – Jun 15, 2025

Kyoto City KYOCERA Museum of Art

Apr 12 – Jun 29, 2025

TOGURI MUSEUM OF ART

Mr. Kanda was born in Tokyo and his interest in manufacturing was naturally developed through the influence of his father who ran a press factory. Even as a high school student he had already decided that he wanted to be involved in the product development of wooden manufacturer. Mr. Kanda says that when he thinks about the future, he wants to connect with society through manufacturing. After graduating, he studied industrial design and gained experiences in the repairing and reupholstery of antique furniture. In 2009 he joined Hida Sangyo in Gifu Prefecture. At first, he was in charge of the manufacturing of custom-made order, and subsequently, he moved to the development division which was what he had wanted to do all along. Currently, Mr. Kanda is engaged in the prototyping and development of new products. He is also involved in the development of furniture using compressed Japanese cedar, which is a special technique of the company. In the development division, there are few opportunities to talk with the customers directly, so the imagination is essential. Mr. Kanda said, “We are doing our best everyday”. He constantly thinks about what type of furniture does society need. “Everyone is putting in 120 percent of effort but is there another one percent that he could add to it”, wonders Mr. Kanda. There is passion for manufacturing in his words.